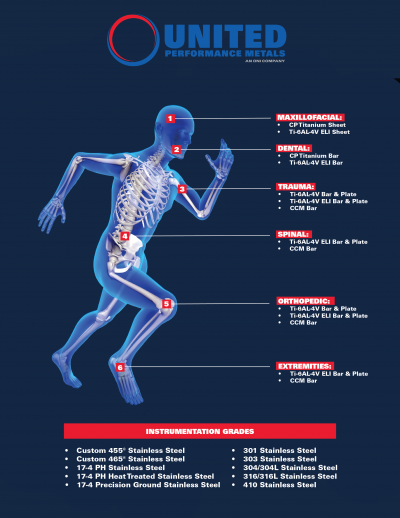

United Performance Metals provides titanium, cobalt chrome molybdenum, and stainless steel for medical applications such as implants and instrumentation. United Performance Metals has ISO 13485: 2016 approval and only buys from approved mill sources as required by the top medical OEMs.

Titanium: UPM stocks Ti-6AL-4V standard and ELI, as well as CP Grades 1, 2, 3, and 4, in bar, plate, and sheet forms. Titanium is popular amongst the medical industry due to its excellent strength to weight ratio, its non-magnetic properties, and the fact that it is one of the only five biocompatible raw materials that the human body will accept. Titanium is commonly used for implants where strength and increased mechanical properties are required, such as resetting large bones.

Stainless Steel: UPM stocks 316/L, 410, Custom 455® and Custom 465®, 17-4 PH/Heat Treated/Precision Ground in bar form. 17-4 PH, 301, 304/L, 316/L, and 410 are carried in sheet and coil forms. 17-4 PH, 303, 304/L, and 410 are carried in plate form. Stainless Steel is widely used in the medical industry due to its exceptional corrosion resistance, formability, and the fact that it is easy to sterilize due to its non-porous surface. Stainless steel is commonly used for surgical instruments such as drills, reamers, and taps, and can also be used for nails, bone screws, and orthopedic implants.

CCM: UPM stocks Cobalt Chrome Molybdenum (CCM) in bar form in thickness ranging from 0.250” – 2.0”. CCM is used in the medical industry due to its strength, corrosion resistance, and biocompatibility. CCM is often used within the medical industry to make implants and dental prosthetics. Some of these applications include knee and hip replacements, shoulder replacements implants, spinal rods and cages, disc replacements, and fracture fixation.

Posted February 20, 2025

Return to Blog