Having state-of-the-art cutting-edge equipment and machinery for build plate manufacturing, finished parts, and additive consumables is crucial for ensuring precision and efficiency in manufacturing processes. Advanced machinery allows for precise fabrication of build plates, ensuring optimal performance and longevity in demanding applications. Additionally, it enables accurate resurfacing and machining, ensuring smooth and precise surfaces essential for quality end products, while laser marking and precise measuring systems ensure traceability and adherence to strict quality standards, ultimately enhancing overall productivity and customer satisfaction.

OUR EQUIPMENT & MACHINES

GF Cut AM 500 Wire EDM machines featuring interchangeable tooling. Reduce total build time and maintain part integrity with small diameter molybdenum cutting wire. Separate 3D printed parts from large build plates with a weight up to 500 kg. Customizable collection baskets ensure parts are undamaged.

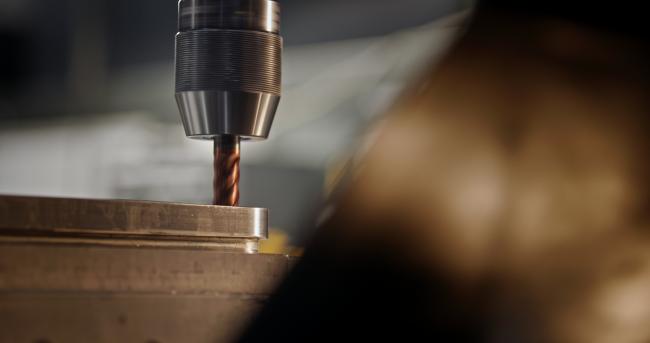

Experience precision machining with the Haas Milling Center. The 50 Taper milling centers offer exceptional accuracy and efficiency for a wide range of machining applications, with flexibility of 3-axis machining and an optional 5-axis capability. Operating at speeds up to 7.5K RPM, and a generous 30+1 tool capacity, the most complex projects can be handled with ease.

UPM Additive Solutions simplifies grinding tasks with our in-house grinding capabilities. Featuring a grinder equipped with a 42” table size and capable of maintaining flatness and parallelism of 0.0004 or better, depending on the size of the plate and material. Our grinder can handle the following materials and more: Aluminum, Steel, Stainless Steel, Titanium, Nickel, Copper, CCM, and HastX.

The Mazak Mega Turn 900 is a vertical turning lathe renowned for its precision and versatility. With a maximum machining diameter of 36.22 inches and a spindle speed of 1260 RPM, it delivers rapid material removal and exceptional surface finishes. Equipped with a 12-tool capacity, it offers flexibility in tool selection for various machining tasks.

The Okuma Milling Center 40 Taper, featuring a standard 3-axis configuration with an optional upgrade to 5-axis capability, represents a versatile solution for precision machining tasks. With a formidable spindle speed of 12,000 RPM and a tool capacity of 32, exemplified by the Genos M560 model, it ensures swift material removal and accommodates a wide range of cutting tools for enhanced efficiency.

The Glass Bead Blaster Clemco Industrial Blast Cabinet Model BNP 55S is a cutting-edge solution for achieving surface finishes with precision and consistency. Featuring a 20” rotating table, it facilitates efficient handling of workpieces for comprehensive blasting coverage. Capable of achieving a uniform surface of 7RA or better, it ensures the highest quality results for a variety of applications. Its adaptability allows for the fitting of additive base plates to attain specific surface finishes or to meticulously refine parts by eliminating imperfections.

The Hexagon CMM is a metrology solution designed to elevate precision measurement to new heights. Equipped with a motorized head with full rotational capabilities, the CMM ensures flexibility and accuracy in inspecting geometries from multiple angles. Housed within a climate controlled clean room environment, the CMM maintains optimal conditions for precise measurements, free from environmental interfere. Featuring the Global S 9.20.8 Scan + Basic model, offers a measuring range of 900mm x 2000mm x 800mm.

The Faro Quantum M Arm helps with precision measurement. With probing and blue light scanning capabilities, it helps deliver unparalleled accuracy in capturing detailed geometric data. Features include comprehensive GD&T measurements, this tool will help in dimensional inspection.

The Keyence WM Series Measuring Machine is a cutting-edge solution for precise measurement tasks. With a 30-foot measuring range, it accommodates a wide variety of workpieces, enabling comprehensive dimensional inspection. The tripod sensor and handheld probe helps with on-shop-floor applications and in-process inspections.

The LaserGear Qube Laser Marketing System offers precision engraving capabilities within a 4” x 4” per pass range. This is used to mark parts with serial numbers for streamlined inventory management.