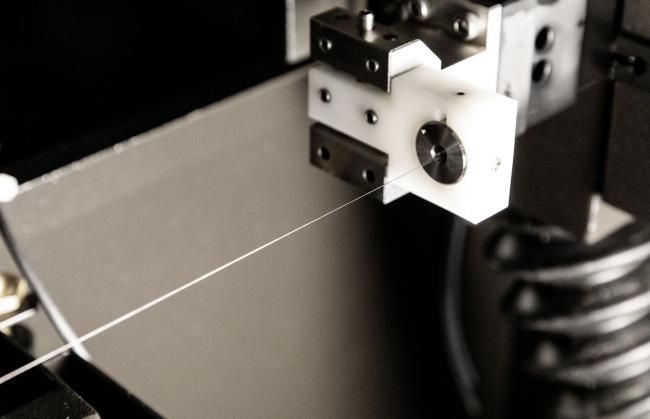

UPM Advanced Solutions skilled EDM experts leverage cutting-edge GF Cut AM 500 Wire EDM machines featuring interchangeable tooling. Wire EDM is the process of separating additively manufactured metal components from build plates, preserving geometrical precision and ensuring readiness for assembly. Its advanced technology enables intricate cuts, delivering results that exceed the most demanding standards of precision engineering.

PART CUT OFF SOLUTIONS

- Designed to cut parts on any powder bed fuser.

- Horizontal wire cutting reduces total build time while maintaining part.

- Tilting table separates 3D printed parts (up to 500kg) from large build plates.

- Customizable collection baskets ensure that parts are fully protected.

PART STRESS RELIEF THROUGH FINAL INSPECTION

- Heat treating solutions (Stress Relief, Heat Treat, Solution Age, HIP)

- Support Removal

- Post Print Part Machining

- QC Inspection

- Laser Marking